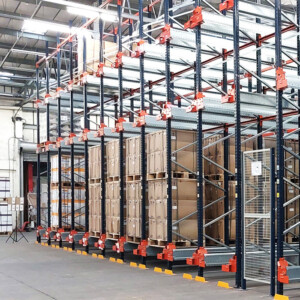

Maximised Storage Space

Pallet shuttle racking significantly increases storage density compared to traditional adjustable pallet racking. By reducing the need for wide aisles and forklift movement within the racking, this system allows you to store more pallets in the same footprint.